Single-acting seal comprising a thermoplastic jacket acting as a seal and that houses a spring which enables the jacket to seal even at low pressure.

DANAFLEX® exhibits: Extreme extrusion resistance – The lowest friction forces – No drift in performance over time

DANAFLEX® seals are custom designed & made, depending on the operating conditions.

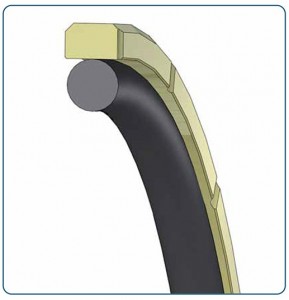

Double-acting composite seal comprising a dynamic sealing pad with multiple sealing grooves and an elastomer O-ring energiser. DANAROTO® are particularly well suited for oscillating and rotary movements.

Benefits of DANAROTO® include: Preventing ingress of abrasive particles into bush-bearing assemblies for extended service life – Low friction, low energy consumption – Excellent extrusion resistance with well proven reliability

DANAROTO® seals are custom-designed and made depending on the operating conditions.

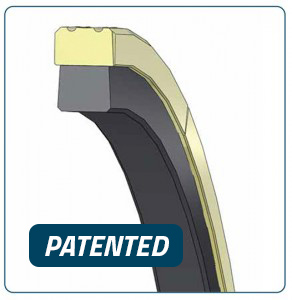

Patented double-acting composite seal for ISO 7425/1 type grooves, DANAWING® comprises a dynamic sealing pad with multiple sealing edges and a trapezoidal shape rubber energiser.

DANAWING® exhibits: No oil film between chambers, no pressure loss and excellent position holding – Precise positioning – Excellent sealing, even at low pressure – No random effect – Very low friction.

DANAWING® seals can also be engineered to fit non-standard grooves and work in extreme operating conditions.

Double-acting composite seal – conforming to ISO 7425/1 – comprising a rectangular dynamic sealing pad and an elastomer o-ring energiser.

DANAGLIDE® exhibits: Narrow footprint – Reduced stiction effect from standstill – Low friction, low energy consumption – Excellent extrusion and abrasion resistance => well proven reliability!

DANAGLIDE® seals can be dimensioned to fit non-standard grooves and made from many materials, depending on the operating conditions.

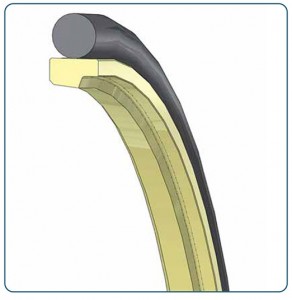

Double-acting composite seal comprising a high-performance thermoplastic “low profile” dynamic sealing pad and an elastomer O-ring energiser.

DANACAP® exhibits: Low friction – Good resistance to extrusion – Resistance to high pressure conditions – Ability to cope with high radial eccentricity – Excellent abrasion resistance with extend service life.

DANACAP® Special seals can be designed and manufactured from many materials, depending on the operating conditions.

Single-acting composite seal for ISO 7425/1,type grooves. DANASTEP® comprises a profiled dynamic sealing element and an elastomer O-ring energiser.

DANASTEP® exhibits: No stick-slip effect – Low friction, low energy consumption – Excellent extrusion resistance – Well proven reliability in demanding applications.

DANASTEP® seals can be designed for non-standard grooves and manufactured from other materials than those listed above, depending on the operating conditions.

OSIS® is an innovative On-Site Injection System used to join large diameter spliced PU seals.

The ultra-portable OSIS® system (<2kg) ensures: Perfect seal profile continuity – High seal joint integrity during equipment maintenance with no loss in mechanical strength, as can be experienced with other seal joining techniques.

REPKOT® is a cost-effective alternative to hard guiding solutions traditionally based on bronze, metal-coated parts or bimetallic components.

REPKOT® can also be used as a direct substitute for phosphor bronze in bush bearing sleeves.

Benefits of using REPKOT® include: Self-lubricated (no need for polluting lubricants) – High compression load resistance – High wear & abrasion resistance leading to longer service life – Low humidity absorption for dimensional stability

Other interesting properties: Electrically insulating, vibration insulating – low density – non-toxic – can be machined.