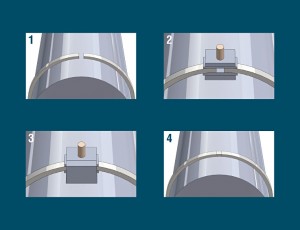

The ultra-portable, OSIS® system ensures a completely homogeneous, high integrity sealing joint during equipment maintenance, avoiding the loss in mechanical strength experienced with other seal joining techniques.

Large diameter, homogeneous seals are often replaced with split seals during the first scheduled maintenance interval, in order to avoid the time and cost of dismantling equipment. Current seal joining techniques suffer from various mechanical and structural shortosis-etapescomings such as a poor jointed finish, however.

The Repack-S OSIS® system ensures a much stronger seal joint. It uses advanced polyurethane compounds, precise injection metering and real-time control of the moulding parameters to achieve a homogeneous joint, as well as a perfectly continuous seal profile.

Repack-S‘s OSIS® on-site polymer injection system is patented and includes the world’s smallest, PLC-controlled injection press (<2kg) for maximum portability, ensuring seal joints with the highest possible mechanical integrity.

Repack-S sealing solutions include a range of proven seal designs: HPX®-Mono®, DANAFLEX®, DANAROTO®, DANAWING®, DANAGLIDE®, DANACAP® and DANASTEP®. All these solutions, when specified properly, offer highly effective, long-lasting and utterly reliable sealing performance.